by Andrei V | Nov 23, 2016 | Common Hose Failures -

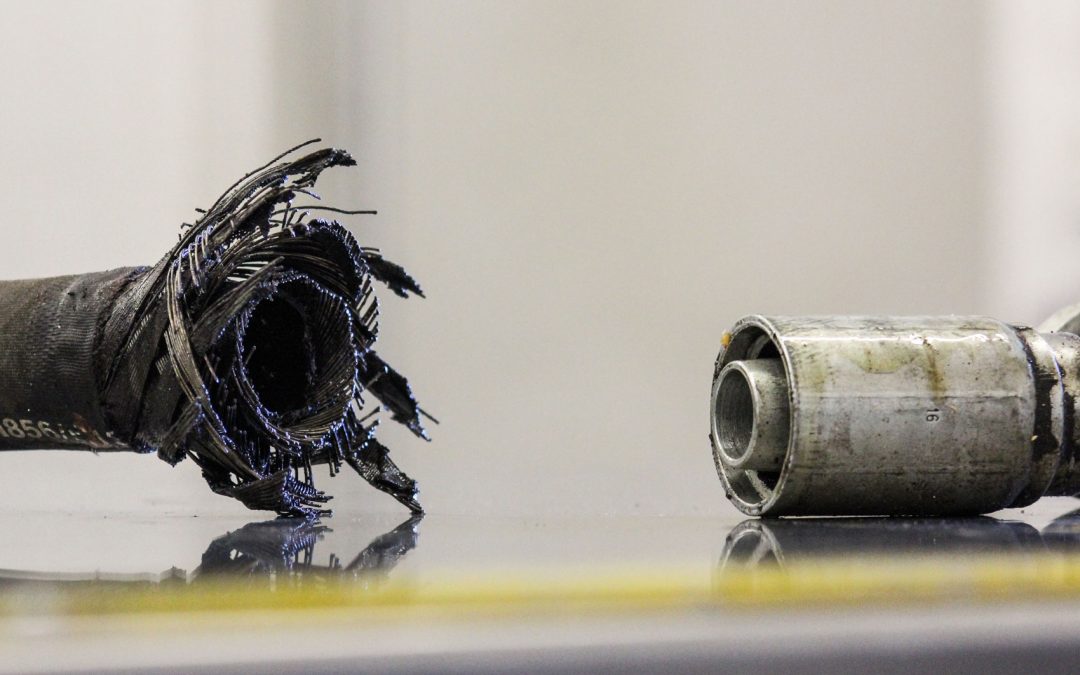

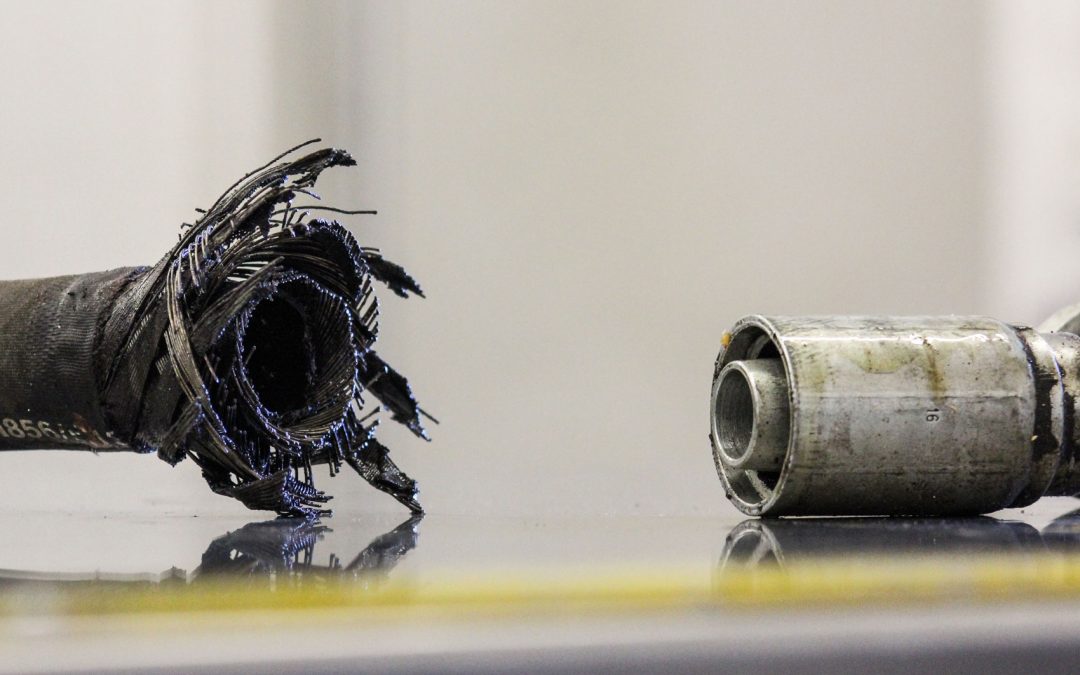

This is the most common and dangerous type of failure in hydraulic hose assembly. Not pushing the fitting down far enough to its maximum crimp depth will always result in a leak or blown fitting. A blown fitting can cause injury or death. HOSE REPAIR SOLUTION...

by Andrei V | Nov 23, 2016 | Common Hose Failures -

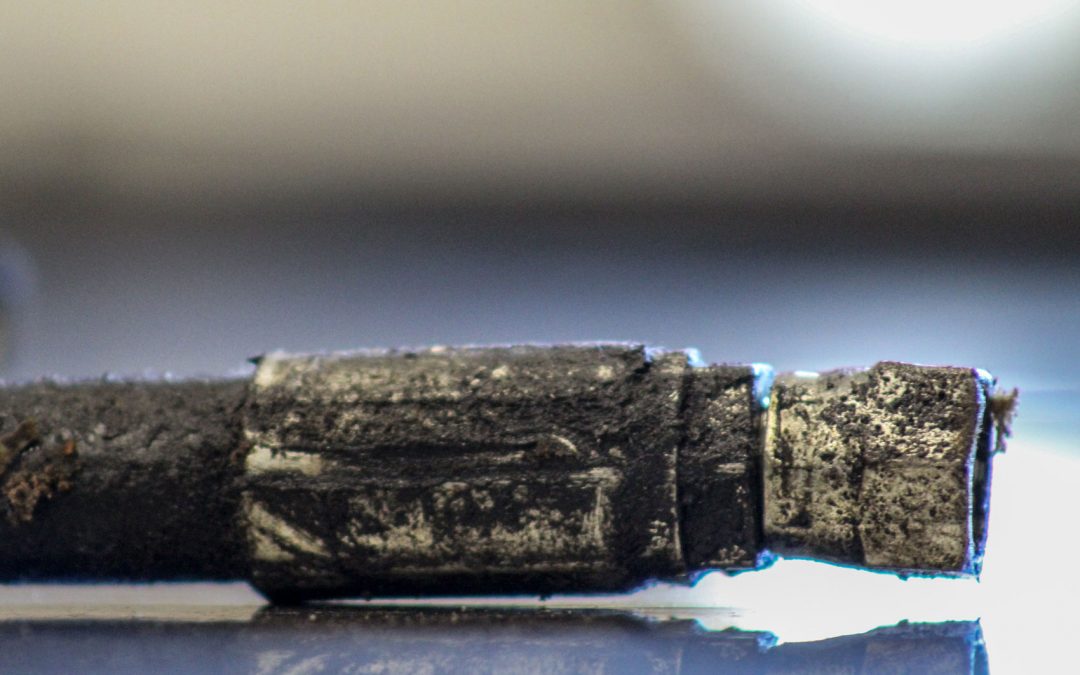

External damage can occur when a hose vibrates or rubs against something on the machine. HOSE REPAIR SOLUTION We provide a custom built hose assembly to match the original hose, this time providing an oil, fire, and abrasion-resistant sleeve around the entire length...

by Andrei V | Nov 23, 2016 | Common Hose Failures -

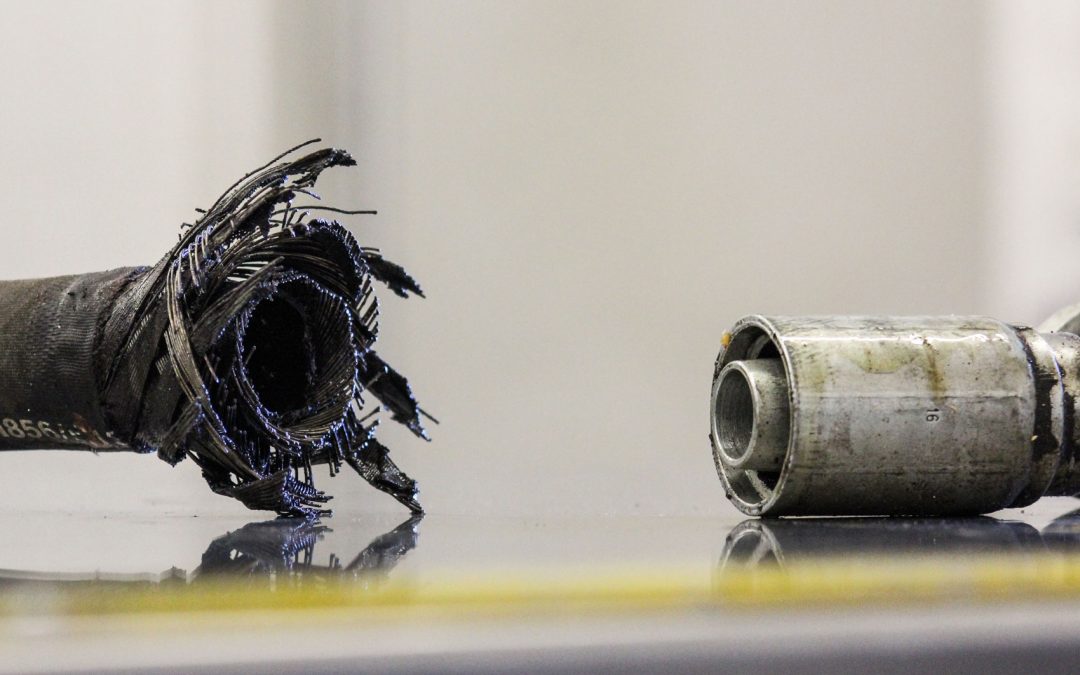

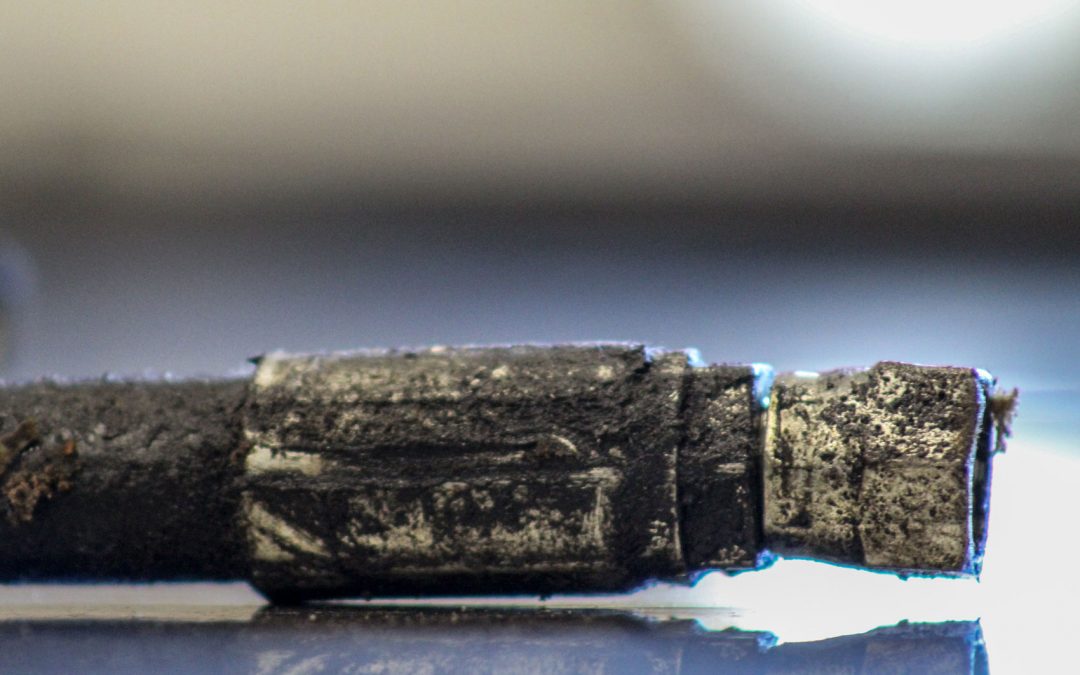

This occurs when a rubber coated, wire braided hose has been on a machine past its useful life. Once the rubber coating on the outside of the hose breaks down and crumbles, the wire braids on the interior become exposed. The weakened hose is very susceptible to...

by Andrei V | Nov 23, 2016 | Common Hose Failures -

Over time, original hoses can wear and burst due to things like overuse, age, and dry rot. HOSE REPAIR SOLUTION We will custom build a replacement hose assembly, utilizing industry-standard materials and high quality...

by Andrei V | Nov 23, 2016 | Common Hose Failures -

A damaged swivel is usually the result of installation error. Most swivels fail when overtightened, resulting in stripped threads and strain on the neck. HOSE REPAIR SOLUTION We will custom build a replacement hose assembly to match exactly the specifications of the...